The new device is based on the best features of Forcit’s previous input units ECM1, ECM2 and NT (Nobel Technic), combined with emulsion sensitizing equipment designed according to the latest research results, as well as the completely new ForSmart control system technology and accompanying cloud services.

Modular concept – flexibility for different inputs

The goal of the product development project was to create a modular and as late as possible variation point batching device concept, from which standardized and pre-planned 1- and 2-pump type batching units for tunnel and production mining can be easily and quickly built as follows:

- Face 1P: 1-pump tunnel injection device o 1 pump module, 1–2 charging coils astern

- Face 2P: 2-pump tunnel injection device o 2 pump modules, 1–4 charging coils astern

- Multi 1P: 1-pump tunnel and production input device o 1 pump module, 1-2 charging coils + production charging equipment

- Multi 2P: 2-pump tunnel and production input device o 2-pump modules, 1-4 charging coils for the stern drive + production charging equipment

- Production 1P: 1-pump production input device o 1 pump module + production input hose handling device

The late variation point enables the construction of different sub-modules even in advance without precise information about the final destination. Modularity makes it possible to change and rebuild machines by changing, adding or removing modules for the next customer need.

Depending on the pump unit, charging can already be done on one line or on two lines using the optional replacement charging function. Line-specific staking can be done as shore staking mechanized using a hose reel or manually charging the holes full.

As completely new and modular features, the ECM3 device will be launched with a 2500 kg matrix tank approved for ADR transport, which enables the device to be moved between two tunnel sites on a public road without the need to empty the tank, and an 800 mm diameter hose reel, which enables better visibility past the reel compared to the previous 1100 mm diameter reel. The hose length in the new and old hose reel is the same 14 m.

The basic solution of the ECM3 is similar to Forcit’s earlier betting units. The operating voltage is 400 V, and the machine can be connected either directly to the tunnel’s power line or, alternatively, to the mobile platform’s own power system. Other operating voltages such as 690 V and 1000 V can be used with the help of a separate transformer.

The ECM3 device has one ForSmart PLC unit, which is capable of controlling all functions of machines with both 1- and 2-pump configurations. The number of electrical cabinets has been reduced compared to the previous NT 2 pump device, which uses two separate pump-specific PLCs.

Precision and power for handling the injection hose with servo motors

In contrast to previous equipment models, in ECM3, servomotors are used not only in the hose feeder of the production input, but also in the hose reels of the stern drive. The use of servomotors in long-hole injection produces a better force for feeding the injection hose compared to hydraulic feeding devices found on the market. The use of servomotors in the stern drive hose reels, on the other hand, enables a more accurate shore application compared to the hose reels of the previous generation of machines with traditional electric motors or the hydraulic hose handling devices found on the market.

The new ForSmart control system – ease of use and cloud services for charging

In the new ForSmart control system, the principle is to use only one program code, which contains the features needed by all the different tunnel and mining equipment, pre-programmed. This avoids several different machine unit-specific program versions. Various features and functions of the ECM3 machine can be activated and deactivated easily from the program settings. For example, changing a 1-pump machine to a 2-pump machine can be done at the machine’s control system level by changing one setting by the person responsible for building the machine. Similarly, changing the number of hose feeders (1–4 pcs) for tailings or adding a hose feeder for production mining can be easily determined at the site by the Forcit Site Manager in the control system’s settings menu.

The new control system includes three different simple user interfaces for defining and selecting the tunneling investment recipes and hole settings. The Mode 1 user interface is completely new and developed especially based on the wishes and usage of Norwegian users. It is especially suitable for long ones with the same tunnel profile for the lining of tunnels made as overburden mining. The Mode 2 user interface is based on the way of using the ECM2 unit that has become familiar in Sweden, where the betting recipe is selected with a separate manual switch. The Mode 3 user interface resembles the user interface of the ECM1 device adopted by Finnish users, where all functions, including the selection of the betting recipe, are done with the help of a remote control. The actual betting screen is the same on all three user interfaces (picture 2). The language versions of the control system are Finnish, Swedish, Norwegian and English.

Other languages can be used if necessary. Each interface has slightly different remote controls. The Mode 1 and 2 remote controls are similar in type to the controls used on earlier ECM2 units. The Mode 3 remote control is identical to the ECM1 units previously used in Finland.

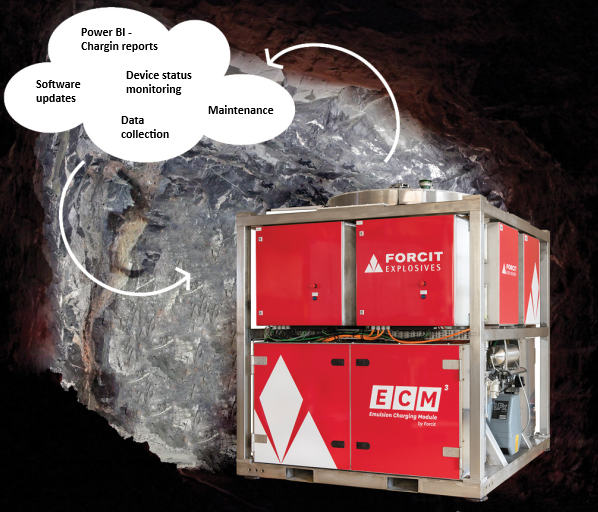

The ForSmart control system comes standard with cloud services included in the system and optional cloud service extensions. The cloud service is used e.g. for maintaining unit-specific user rights, sharing investment reports, software updates, maintenance and collecting and analyzing big data. Big data collection utilizes the OPC UA standard developed for industrial equipment communication and the existing ForDEX software package. Investment reports can be distributed to customers via the cloud service as a ready-made Power BI report (Figure 3). Software updates take place in ForSmart’s DevOps environment partially automated, but still manually approved by the operator. Remote connections can be used to determine the need for preventive maintenance and fault diagnosis.

Production program for ECM 3 machines

The ECM3 prototype was built as a Face 2P version (2-pump tunneling device) with a 2500 kg matrix tank approved for ADR use in early 2021 and has been tested during the summer and autumn in Vihtavuori and under real operating conditions in the Pyhäsalmi mine. In addition, the installation of three new Face 2P machines for Nordic customers is underway.

It is possible to implement the new ForSmart control system and cloud services in old ECM1, ECM2 and NT devices by replacing the existing control system with the new ForSmart system. The first renewal project of the previous generation ECM1 unit is already underway. In the renewal project, the originally 1-pump ECM1 tunnel injection device, which was in continuous use by a Finnish customer, will be changed into a 2-pump Face 2P machine.